Rethinking our reliance on single-use plastics in foodservice

-

-

Nurul Aisyah Suwandi

-

July 4, 2022

-

6 min read

Nurul Aisyah Suwandi

July 4, 2022

6 min read

When the Covid-19 pandemic hit, lockdowns and social restrictions meant restaurants could not operate at their usual capacity, causing a decline in foodservice sales and a shift towards more delivery and takeaway. Across India and Southeast Asia (SEA), foodservice sales decreased by approximately 36% due to the lockdowns in 2020.1 Foodservice operators had to quickly pivot from dine-in to delivery or takeaway, causing single-use plastics (SUPs) use to surge with the greater utilization of disposable cutlery, takeout containers and packaging.

Policymakers and corporates are acting on single-use plastics, but can small operators join the efforts?

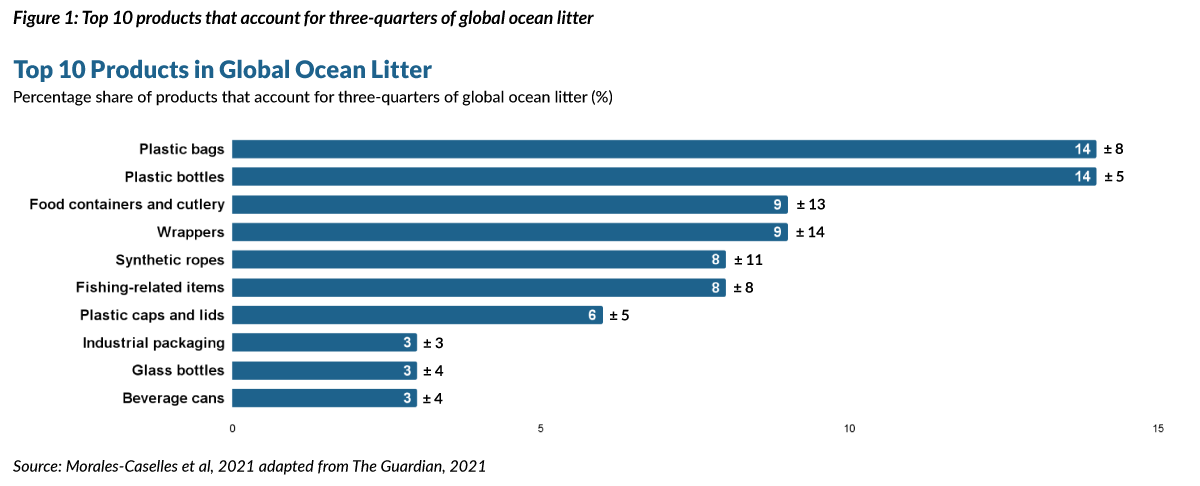

The subsequent growth in SUP waste has contributed to ocean plastic pollution, a growing challenge for many emerging markets. In fact, SUP items from takeaway food and drink are amongst the top three products found in global ocean litter (Figure 1). The management of SUP waste and reduction of its use has been high on the agenda for policymakers in India and SEA, and a number of countries in the region have set roadmaps and targets to address the issue. Gradual phasing out of items such as cutlery and plastic bags are increasingly being incorporated into national regulations, such as India’s Plastic Waste Management (PWM) rules and the Philippines’ Single-use Plastic Products Regulation Act. These policies nudge users or producers of SUPs in the right direction, and if implemented effectively, can significantly reduce their use.

In the face of increased scrutiny, global brands and food service operators have drawn up sustainability commitments, which include the elimination of SUP products, or switching to alternative materials. Others have committed to improve the recyclability of their packaging, increase recycled content and adopt refill or reuse models. Starbucks is working towards incorporating 20% recycled content into their hot cups by 2022 and is testing reusable cup share programs in different regions.

Local foodservice operators are also making efforts to reduce their plastic footprint. However, when seeking to replace SUPs, there are several factors that operators should consider, to ensure they do not cause more environmental damage.

What should foodservice operators consider when seeking to replace single-use plastics?

Reusable container programs, material alternatives such as bioplastics, paper or fiber: SUP replacements can come in many different forms. When deciding on the best alternative, an active evaluation of the food service operator’s needs should be conducted to assess the points of intervention for SUP replacements, with three key considerations in mind – convenience, cost, and the environmental impact.

Convenience

Maintaining convenience for consumers is key to ensuring that they can easily switch to the alternative solution, particularly for refill or reuse types of alternatives. As consumers have become reliant on the convenience of the ‘use and throw’ of SUP, a change in mindset is necessary for them to bring their own reusable containers or return reusable packaging provided by the operator. To overcome this, operators, either individually or collectively, will need to develop a reuse program that makes it easy for consumers to do their part at no additional cost.

Cost

Cost is another factor that is of concern for some foodservice operators. Due to their early developmental stage, most alternative solutions such as bioplastics tend to be much more expensive than SUPs, even as much as two to five times the cost. For refill/ reuse models, the logistical cost of having to collect, clean, and redistribute the items contributes to their higher price tag. With margins already eroded due to increasing raw material costs, exacerbated by the pandemic, some operators cannot afford to switch to these costly alternatives. Operators with fewer outlets, unlike chained operators, would face higher cost pressures and find it difficult to procure alternatives at a lower cost price, due to the lack of economies of scale.

Environmental impact

Understanding the environmental impact of a product involves reviewing each stage of its life cycle from cradle to grave. The environmental impacts of these alternative solutions can include the greenhouse gas emissions associated with the product/ service’s lifecycle, energy resources utilized to manufacture the product, and the amount of water consumed during the use and maintenance of the products (for reuse solutions), or even in the manufacturing processes. SUP replacements need to do better, not only in solving the plastic waste issue but also in providing environmental benefits over the status quo.

Depending on the type of food service operator, and their proximity to waste management infrastructure, for example, different solutions may be more environmentally beneficial than others. Biodegradable packaging or some biobased packaging requires the right composting facilities to ensure proper disposal. When it comes to reusable containers, operators would have to consider the environmental impacts associated with reverse logistics, such as the energy and water used for transport and washing of the returned containers.

Scaling up SUP alternatives needs support via incubation and collaboration

The current landscape of SUP alternatives is populated by early-stage solutions that need to be scaled to ensure they can compete with plastic items already on the market. These startups often struggle with a lack of capital, underdeveloped value chains, and complex policy and regulatory frameworks. Food service operators are also unaccustomed to working with these early-stage solutions and tend to rely on their established supply chains.

The Circulate Initiative is a non-profit organization committed to solving the ocean plastic pollution challenge by incubating solutions and generating insights to accelerate investment into advancing the circular economy in South and Southeast Asia. Through our work with The Incubation Network, we support and scale these early-stage solutions through programs such as The SUP Challenge. Funded by the PREVENT Waste Alliance and ECCA Family Foundation, the challenge provides capacity building and opportunities for these ventures to pilot their solutions with F&B partners across India and Southeast Asia, through the facilitation of partnered entrepreneur support organizations (ESOs). Along with our research partner, PXP Sustainability, The Circulate Initiative will also be conducting an environmental impact assessment on some of these solutions to explore their best use cases for different foodservice channels. Ultimately, these initiatives are designed to identify investible alternatives to SUPs that can be scaled to meet the needs of food service operators.

Collective action in the foodservice industry can help accelerate the reduction of single-use plastics

Alongside efforts to incubate alternative solutions, collective action within the foodservice industry can also accelerate the uptake of SUP alternatives. This is especially important for refill/ reuse systems which bring with them additional logistical requirements for businesses to manage their reusable packaging. A system design standard developed by PR3, a private-public partnership for reusable packaging launched by Resolve2, is an example of cooperation that can help small businesses better manage the cost of logistics and infrastructure required for the washing, labeling, and transportation of reusable packaging.

Similarly, the bargaining power of operators and suppliers can also have a bearing on the decline of SUP, enabling them to influence suppliers to provide an alternative that works for all players. The old adage, power in numbers holds true. For small players who lack influence, small players can unite with a shared voice to drive real change.

References:

1Euromonitor International, 2021

2Reusable Packaging System Design Standard.